Top 10 Plywood Manufacturer Company in India

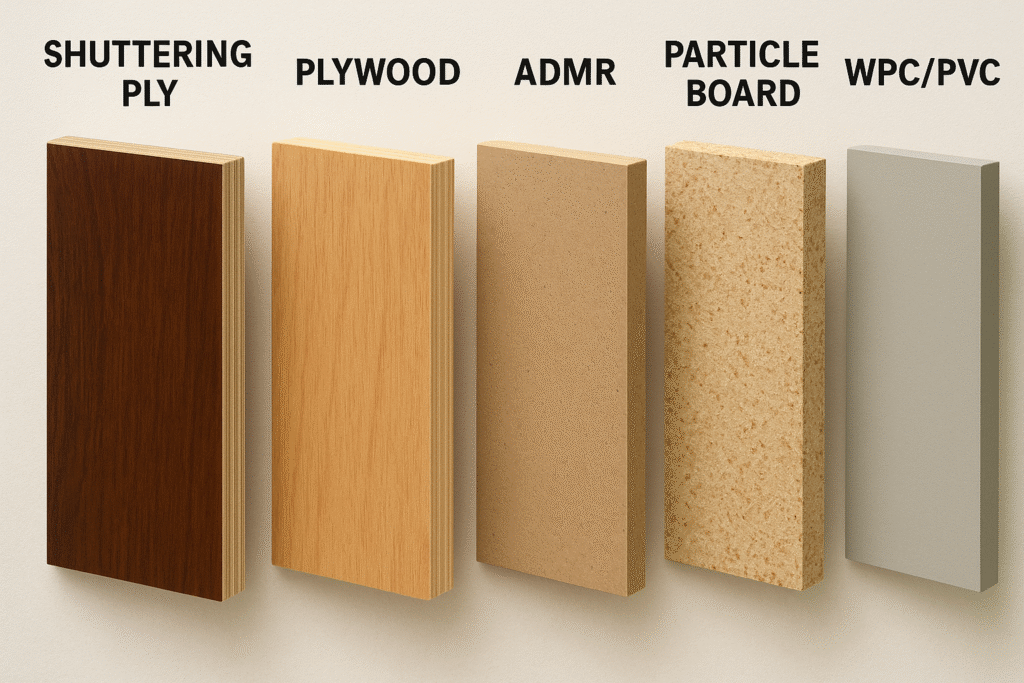

India plywood sector has seen impressive growth over the years which is fueled by rising demand from residential, commercial and infrastructure projects. Among the various brands in market, Haren Ply has made a name for itself as one of the top 10 plywood manufacturer in India, due to our dedication towards quality, innovation and customer satisfaction. A reliable plywood manufacturer provides a wide range of engineered wood products that is customized to meet the modern construction and interior requirement throughout the country. Here is the list of top 10 plywood manufacturer: 1. Century Plyboards Ltd. 2. Kitply Industries 3. Green Ply Industries Ltd. 4. Haren Ply 5. Sarda Plywood Ltd. 6. Mayor plywood Ltd. 7. Duopoly industries Ltd. 8. Austin Plywood Industries Ltd. 9. Sharon Ply 10. Timex Plywood Ltd. A Leading Plywood Manufacturer in Uttar Pradesh: We are known as one of the most reliable plywood manufacturers in Uttar Pradesh, as we serve to different architects, builders, interior designers and furniture producers. The company maintains the strict quality control measure and employs advance manufacturing technology to provide products that ensure strength, durability and long lasting performance. The reliable product quality and extensive distribution network have established us as a favored plywood makers in both urban and semi – urban areas.As a prominent player in the local market we meet the need of high quality plywood and related products. Our prime location enables us to offer quick deliveries, competitive prices and reliable after sales service which helps us in earning a solid reputation in North India. Expertise as ADMR & HDHMR Manufacturer: We are known as a reliable ADMR & HDHMR manufacturer that provides a high density boards as these boards are recognized for great screw holding capabilities, smooth surface finish and outstanding machinability. These boards are perfect for modern furniture, cabinetry and high end interior uses, which further enhances the brand standing in the engineered wood market. Trusted Waterproof and Marine Plywood Solution: We are recognized as the top waterproof plywood manufacturers and supplier of waterproof plywood. We are capable of manufacturing the high quality waterproof plywood with resin and advance bonding method to ensure moisture resistance and long lasting durability. Additionally, mainly companies and clients choose the marine plywood manufacturers those are looking for the marine plywood in Uttar Pradesh. This type of plywood is crafted to handle harsh moisture environment which makes it perfect for kitchen, bathroom, coastal region and other marine setting. Renowned Gurjan & Hardwood Plywood Manufacturer: Haren Ply stand among the gurjan plywood manufacturers & hardwood plywood manufacturers in India. We use high quality hardwood timber to create plywood that offer reliable strength, stability and durability. These products are widely used in premium furniture, doors and strong structural use. Fire Resistant Plywood Manufacturer and Supplier: Safety is becoming one of the most important concern in today’s construction world and we are setting up to meet the demand of a reliable fire resistant plywood manufacturers and supplier of fire resistant plywood in India. The fire retardant plywood is designed to slow down the spread of fire which makes it perfect for commercial building, offices, hotels and public infrastructure. Diverse Range & Customer Trust: We at Haren ply set itself as the plywood manufacturers with a wide range of products like flush doors, block boards, shuttering plywood, PVC WPC and laminate creators. This diverse collection allows customer to find multiple interior and construction solution from a single reliable source. The company has earned the reputation among the top 10 plywood manufacturer in India with its consistent quality, compliance to meet the Indian standards, eco friendly practices and a strong focus on customer service that builds the long lasting trust in the Indian market. Conclusion: In a tough plywood market, Haren Ply shines bright because of its high manufacturing standards, wide variety of products and solid regional presence. Whether you need an ADMR manufacturer, marine plywood manufacturer, shuttering plywood In Uttar Pradesh or a reliable plywood manufacturer in Uttar Pradesh, we consistently delivers excellence at every level. These attributes clearly show why we proudly ranks among the top 10 plywood manufacturers in India and remains the best choice for quality focused customers all over the country. Frequently Asked Question: How do I choose the best plywood manufacturer in India? You can choose plywood manufacturer that offers ISI certified products, advance manufacturing, diverse product range and reliable market reputation. Which plywood brand is best for home furniture in India? The plywood brand like Haren Ply provides the best home furniture as they provide high quality waterproof plywood, hardwood plywood, gurjan and HDHMR plywood which is suitable for long lasting interiors. What is the difference between commercial plywood and marine plywood? The main difference between commercial plywood and marine plywood is that – Commercial plywood is suitable for dry areas where as Marine plywood is suitable for high moisture prone areas like kitchen & bathrooms. Are all top plywood manufacturers in India ISI certified? Mainly the reputed manufacturer like Haren Ply follows the ISI standard to ensure strength, durability and safety. What is the average price of plywood in India? The price of plywood varies based on thickness, grade and type of quality plywood that offers the better long term value. Do top plywood companies in India offer warranties? The leading brand offers the warranties that reflect the confidence in their product quality and durability. What is plywood? Plywood is an engineered wood panel made by bonding of multiple layer of veneers that provides strength, stability and versatility. How do I check the quality of plywood? Check the ISI mark, uniform thickness, smooth surface, waterproof bonding and manufacturer creditability. What thickness of plywood should I use? Thickness depends on the usage 6mm to 12mm for paneling, 18mm for furniture and thicker boards for heavy duty applications, How long does plywood last? Plywood can usually last for 20 – 30 years if they are properly maintained and taken from a reliable manufacturer. Is plywood termite-proof? Premium plywood is treated