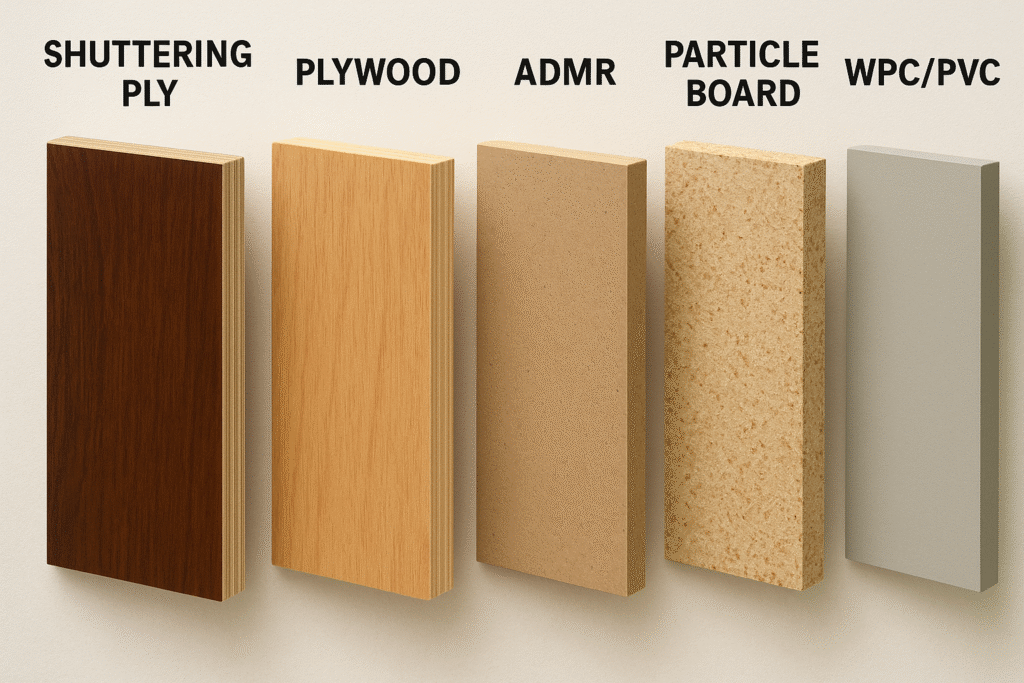

Shuttering Ply vs Plywood vs ADMR vs Particle Board vs WPC/PVC – Right Material, Right Place!

From construction of furniture to building construction plywood is being used in several applications. But unaware of the fact that varying applications require varying plywood or wooden sheets, they often end up investing in similar kinds of material. That is why to make people aware of the same, we at Haren Ply are sharing differences between all these materials including shuttering plywood, plywood, ADMR, Particle Board, and WPC/PVC. This difference will help people understand that all these plywood or wooden sheets are integrated with different features and are used in different applications. We are into this business for a long time and we consider it our duty to educate our customers about the same. Let’s check the difference between all of these below. Shuttering Plywood – Suitable for Construction Work It is one of the heavy-duty plywood which is mainly used in construction work only. It is not a plywood that one should opt for interior decoration or furniture construction. It is helpful in offering support to concrete mixture when building roofs. It is known for its high density which makes it perfect for pouring concrete without worrying about it getting damaged. Features of Shuttering Plywood Sturdy plywood that acts as a mold for concrete work. Offers excellent resistivity to moisture and water. Known for its excellent dimensional integrity. Suitable to use multiple times in construction work if stored and maintained properly. Excellent load bearing capacity and smooth surface for proper construction. Available in 30kg and 34kg weight to meet different building requirements. One with 30kg weight can be used for 7 to 12 repetitions and one with 34kg weight can be used for up to 14 repetitions. Well-built surfaces prevent concrete from attaching to the surface which gives smooth concrete work and eliminates the need for plaster work. Plywood – Suitable for most interior furniture work Whether you need to construct office furniture or home furniture, choosing plywood is what one prefers. But they are also available in 3 different grades, including: BWP Grade Plywood MR Grade Plywood BWR Grade Plywood These are made using carefully chosen wood veneers and softwood or hardwood material, depending on its type. To make them last long, they are glued using high quality adhesives and are prepared under high pressure. It makes them a perfect choice for long-lasting furniture. Features of Plywood Known for their versatility as they are suitable for constructing both home and office furniture. BWP grade plywood that is Boiling Water Proof Grade Plywood is suitable for applications where furniture will be exposed to high amounts of moisture or water. MR grade plywood is suitable for applications where furniture will be exposed to low or minimal moisture or water. BWR grade plywood is for applications where furniture will be exposed to medium level of humidity or water. Among all these three, BWP is known to have high density and excellent sturdiness. Some of the applications they are suitable to use include kitchen cabinets, table, chair, cupboards, office furniture, and outdoor furniture as well. If you wish to get the high quality plywood for any interior work, we recommend buying from Haren Ply. We ensure that we deliver the right quality plywood constructed precisely to meet most requirements with ease. ADMR – High Moisture Resistant Board Unlike shuttering plywood or BWP or BWR grade plywood, ADMR, which is Aqua Densified Moisture Resistant Board, is manufactured using wood fiber. It is also called as Green Densified Board in other words and is known for its excellent moisture resistant property. Though it may not offer excellent performance like BWP or BWR grade plywood, it is better when comparing it to MR Grade plywood. Features of ADMR Known for its high moisture resistivity. Offers smooth surface finishing making it a suitable choice for applying paint or high gloss sheet or acrylic sheet. For areas that have high humidity, choosing ADMR is a reliable option. Known for its affordable prices if we compare it to different types of plywood. It is also one of the reasons why it is a better alternative to MR grade plywood. Suitable to use in kitchen and bathroom applications. Particle Board – Budget Friendly Material Compared with all the above-mentioned plywood sheets and ADMR Board; Particle Board is a cheaper material to go for. For those searching for wooden boards or materials for packaging applications, paneling, or fabricating decorative elements, particle boards are suitable to go for. It is made of wood flakes or wood fiber which makes it a lightweight material and an affordable choice. Features of Particle Board Known for their smooth surface and lightweight. Easy to work with when constructing furniture and decorative items. Do not offer lasting performance but due to their low cost, they can be preferred for constructing objects or furniture that are required only for 1 or 2 years of use. They are also available in laminated and pre-laminated versions. WPC/PVC Boards – Perfect for offering complete water resistivity Unlike all the above-mentioned boards and plywood, WPC or PVC boards are not made using proper wooden material or wood veneer or wood fiber. Instead, they are manufactured using wood plastic composite or polyvinyl chloride. It is their construction that allows them to offer 100 percent water resistivity. But they are not suitable to use for heavy-duty applications as they cannot bear heavy load. Features of WPC/PVC Boards Lightweight boards known for their environmentally friendly construction. Complete water resistivity which prevents it from deforming and warping. A smooth surface allows one to paint on them with ease. No worries about termites when choosing WPV/PVC Boards. Available at affordable price Conclusion We hope now you have understood the difference between all these different types of plywood and boards. So whether it comes to using shuttering ply, plywood, ADMR Board, Particle Board, or WPC/PVC Boards, always consider these points and then only invest in the ones that meet your requirements. Never compromise on quality by choosing a cheaper option for applications that require high quality