Choose the Right Laminates for your home

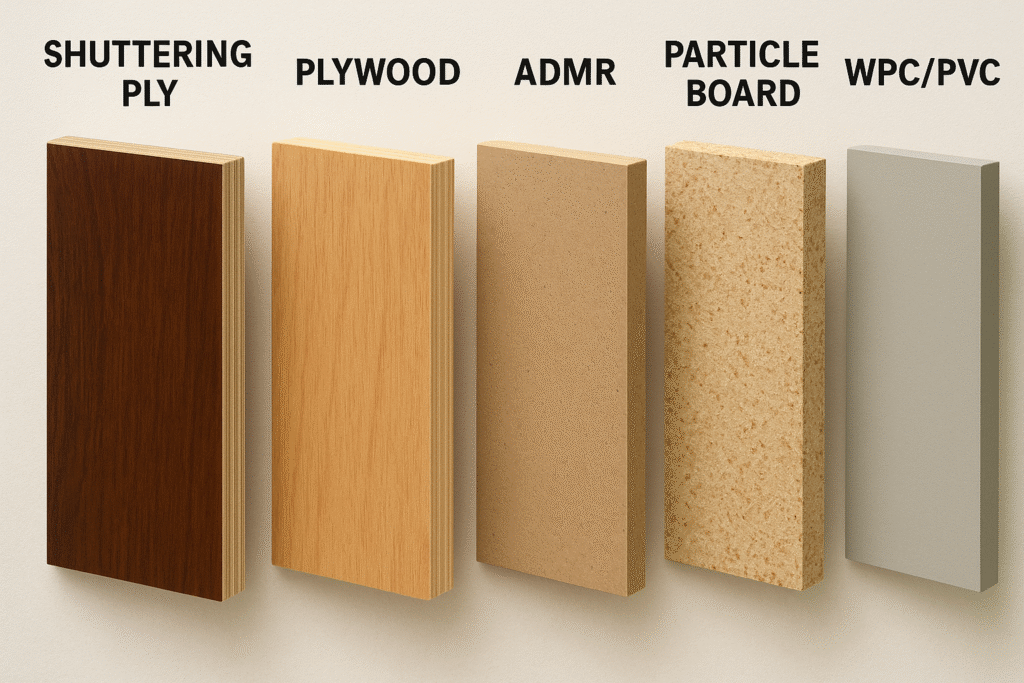

When it comes to home interiors, one of the most adaptable and stylish material available today is laminate. Laminates Manufacturers like Haren Ply provides sleek, durable and comes in multiple number of designs, making it go to choice for home owners, architect and interior designers. Whether you’re updating your kitchen, wardrobe or furniture, laminates can really change the vibe of your space, from ordinary to aesthetic check by providing long lasting performance. When there are large number of manufacturer in the market choosing the right manufacture becomes crucial as the laminate sheet provides durability to your furniture. Here are few steps that help you to choose the right manufacturer of laminates: Understanding the Type of laminate: Before you choose the laminate, take some time to learn about the different types of laminates: Decorative Laminates: They are great for furniture, cabinet and wall panels, available in wide variety of color, texture and designs. High Gloss Laminates: If you want a modern vibe, these laminates bring a shiny and reflective finish to glow up your space. Matte Finish Laminates: They offer a classy and elegant finish, which are scratch and resistant free, making them great for daily use. Industrial Laminates: Designed for heavy duty appliances, which are water and heat resistant proof, best choice for bathroom and kitchens. Match Laminate with Room Finish: Every area in your home has its specific need: Kitchen: Requires high pressure laminates which can handle heat, stains and moisture. Living Room: Decorative or textured laminates which can give an eye catchy look and make your furniture and wall pop. Bedroom: Requires a calm or aesthetic look laminate which can give your wardrobe and side table an aesthetic look. Bathroom: Needs a water – resistance laminate with a solid sealing so that it can go for long run. Think About Visual Appealing: The beauty of laminates lies in wide range of design and finishes. So the Laminates Manufacturers like Haren Ply gives you a choice to choose the right one: Modern look: Choose neutral shades, shiny finishes or metallic laminates. Classic Style: Wood grain laminates in oak, walnut or teak are always a go to choice. Vibrant Space: Experiment with texture or painted laminates that create depth and interest. Check the Quality of The Laminates: Thickness: Go for thicker laminates for better stability especially for high impact areas. Core Material: Look for High Density fiberboard which is a sign of premium quality. Balancing Back: Ensure the laminate has a waterproof backing layer for structural integrity and water resistance. Balance Budget and Longevity: Decorative laminates are budget friendly but high pressure laminates must be costlier as they offer great durability. Rather just focusing on cost consider laminates as a long term investment. A trustworthy laminate manufacturer guarantees that product not only look appealing but also delivers excellent performance over the years. Why to Choose Us? Selecting the perfect laminate for your home goes beyond just looks, it’s also about durability, practicality and lasting value. With reputable Laminates Manufacturers like Haren Ply you can explore wide range of stylish, high – quality and reliable laminate sheets designed to suit every corner of your home. From kitchens to bathroom to wardrobes and living spaces, the right laminate can transform ordinary space into stunning and long lasting look. FAQs:- Why are laminates used in home interiors? Laminates are basically used in kitchens, wardrobes, wall panels etc. to enhance the look of your space and protect surfaces from daily wear and tear. Which laminates are best for modern kitchen? High gloss or high-pressure laminates are ideal for kitchen. They resist stain or moisture to give a premium look to your kitchen. How I choose good Laminate Manufacturer? Check the product quality, certification, durability and customer review like looking for a manufacturer. Can laminates be used in bathroom? Yes, but only high-quality water-resistant laminates can be used so that they can go for long run. How do laminate last in home interiors? It basically depends the kind of maintenance you’re keeping but they usually last for 15 years.